Modern Techniques for Ductile Iron: The Power of SG Iron Treatment

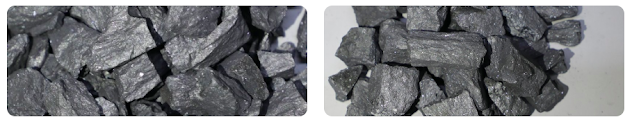

Ductile iron, also known as nodular iron or SG iron (Spheroidal Graphite Iron), stands as a versatile material prized for its superior strength, durability, and ductility. To harness its full potential, modern foundries employ innovative techniques like S G iron treatment , a process facilitated by materials such as FerroSiliconMagnesium (FeSiMg). This dynamic approach plays a pivotal role in enhancing the mechanical properties of ductile iron, making it a cornerstone of many industries. SG iron treatment involves introducing carefully calculated amounts of FerroSiliconMagnesium into the molten iron, transforming its microstructure by promoting the formation of spherical graphite nodules. This modification results in improved mechanical properties, including enhanced tensile strength, impact resistance, and fatigue life. The utilization of precise dosages and advanced metallurgical practices ensures consistent and reliable outcomes. The benefits of S G iron trea...