Ferro Silicon Magnesium Cored Wire: Revolutionizing Steel Production

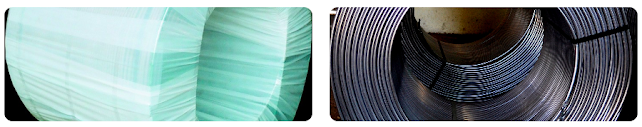

In the world of steel production, constant innovation drives progress, and one such groundbreaking advancement is the Magnesium Cored Wire Injection System . In this article, we will delve into the significance, applications, and benefits of Ferro Silicon Magnesium Cored Wire, also known as FeSiMg cored wire, and how it is transforming the steelmaking industry. Let's take a closer look at this cutting-edge technology and its impact on steel production processes. Understanding Ferro Silicon Magnesium Cored Wire Ferro Silicon Magnesium Cored Wire is a critical nodularizer and desulfurization agent utilized in the production of ductile cast iron. This alloy wire is composed of a combination of elements, including ferrosilicon, magnesium, and other additives, all encased within a steel strip. The outer steel casing allows for precise delivery of alloying elements to the molten metal during the casting process, ensuring controlled and efficient alloying. Advan...